Reel O.D. calculation for tape

When we would deliver the tape roll for customer, we need calculate out:

How many rolls per carton ? What the size of per carton?

How many quantity can be load into a truck or a export container ?

Thus to know the outside diameter of the tape roll is required.

Definitely, we can measure the OD after we produced the tape roll, however,

if you could know the diameter in advance and estimate the loading quantity, then

the transportation cost will be under your control.

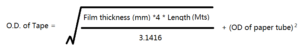

The calculate formula as follows:

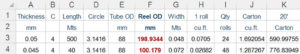

If you’re headache with mathematics, then you may do calculation with EXCEL, as follows:

A & C are key-in by yourself.

B is a constants, no need change.

D is circle (Pi).

E is outside diameter of paper tube; if ID 3 inch core, you may keep 88 at this row.

F3 = SQRT(A3*B3*C3*1000/D3+(E3*E3))

G is key-in by yourself.

I is supposed quantity in per carton.

J is volume of per carton, usually 1-1.5 cube feet is most suitable for handling.

K is suitable quantity to load into a 20’ container, usually take 1000 cu.ft for per 20’ container, in calculation.

Definitely when winding tension is higher then OD will be smaller, but such tape may be telescope;

If winding too loose then the OD will be bigger then loading quantity will be less and pay higher freight.